Opens its largest innovative food solutions facility in Bengaluru

The ready-to-eat (RTE) food sector in India has experienced substantial growth in recent years, driven by evolving lifestyles, urbanization, and increasing disposable incomes. The convenience and time-saving advantages of RTE meals have fueled their popularity among busy urban dwellers, students, and professionals. According to research conducted by SATS, the value sales of RTE meals in India are projected to surge by 45% from 2021 to 2026, reaching an estimated total of US$64 billion. RTE meals encompass a wide range of pre-cooked convenience food products packaged for immediate consumption.

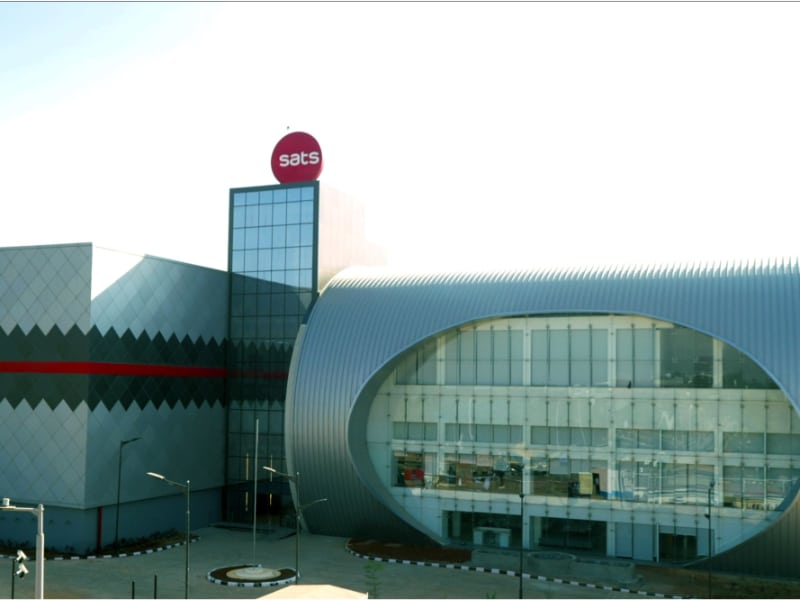

The Ministry of Food Processing Industries (MOFPI) predicts that by 2028, 34% of the Indian population, particularly young consumers and millennials, will exhibit a higher consumption of RTE meals. Additionally, MOFPI notes that the global demand for Indian RTE food products surpasses domestic demand. To cater to both domestic and international markets, SATS Food Solutions India (SFSI), a subsidiary of SATS Ltd., has inaugurated its largest international food solutions facility in Bengaluru, India. This facility complements its existing large-scale food production facilities in Singapore, China, Japan, and Thailand.

The SATS India Food Solutions (SFSI) facility, backed by an investment of SG$61 million, is a frozen food manufacturing plant that combines culinary expertise with cutting-edge technology to produce delicious and nutritious food items adhering to the highest standards of food safety. Beyond just manufacturing products, this innovative food solutions facility, integrated with packaging capabilities, will serve as part of SATS’ global network of Experience and Innovation Centers.

Located near the Kempegowda International Airport in Bengaluru, the facility spans 221,000 square feet and has the capacity to deliver up to 40,000 kilograms of ready-to-eat food products daily to various clients, including institutional caterers, private label brands, and commercial establishments such as large-scale food retailers, restaurants, cloud kitchens, cafes, and lounges, both within India and internationally.

Stanley Goh, the CEO of SATS Food Solutions, emphasized the significance of this facility’s inauguration, describing it as a pivotal achievement for SATS’ food production network in Asia. He highlighted SATS’ reputation as Asia’s premier provider of catering services for leading airlines, commercial entities, public institutions, and food service and retail sectors. Goh underscored the trust that customers place in SATS and its central kitchens in Singapore to deliver top-notch, authentic-tasting food solutions on a large scale, whether on flights or on the ground. He also emphasized SATS’ extensive capabilities across the entire food value chain, spanning procurement, value-added processing, production, commercialization, and distribution, which have evolved over five decades in response to commercial demands and consumer insights.

Transferring this expertise from Singapore to India and drawing upon insights garnered from longstanding partnerships with aviation-focused collaborators in India, the SFSI team will apply SATS’ extensive knowledge in culinary arts, product development, food technology, quality-driven large-scale manufacturing, and innovative packaging. This will facilitate the creation, distribution, and export of food products from the Indian central kitchen, catering to both domestic and international markets.

With our expanded food production capacity in Asia, including the newly established SFSI facility, we are poised to deliver up to 750,000 meals per day. This will drive the evolution of the ready-to-eat food landscape within the SATS network of customers across Asia and beyond, aligning with our mission to nourish and connect communities.

Today, we are thrilled to announce that Swiggy, a prominent Bangalore-based food delivery platform in India, is among the initial brands to join our esteemed SATS customer network. This collaboration will enable us to offer innovative food solutions throughout India.

Rohit Kapoor, CEO of Food Marketplace at Swiggy, expressed optimism about the potential of SFSI to emerge as a leader in large-scale food production in India. He emphasized the importance of their culinary proficiency and expertise in food technology, ensuring that food safety, quality, nutrition, and taste meet the highest standards. Kapoor eagerly anticipates exploring collaborative opportunities with SFSI.

Utilizing robust culinary expertise and leveraging established food technologies, Sagar Dighe, Director and CEO of SATS Food Solutions India, highlighted the company’s global reputation for crafting authentic flavors and employing proven methods to deliver delicious, nutritious, and safe food offerings.

Dighe emphasized the paramount importance placed on food safety, integrity, and quality within SATS’ kitchens, underscoring the acquisition of the FSSAI quality license in India. Additionally, efforts are underway to secure international certifications such as FDA, CFIA, FSSC22000 Food Safety Management System (FSMS), and Medina, ensuring uniformity across all kitchens.

Furthermore, SATS implements industry-proven technologies like the Internet of Things (IoT) to optimize kitchen operations while upholding stringent standards for food safety and quality. For instance, IoT sensors and sensor-based lighting systems have been deployed to monitor energy consumption in real time and oversee ambient conditions such as temperature, humidity, and air quality. These sensors also regulate storage conditions for raw and cooked food to ensure integrity and safety.

Moreover, technology is harnessed to anticipate risks, enhance traceability, and bolster transparency in the supply chain. By digitally documenting the journey of food products from farm to table, critical information including ingredient origins, harvest dates, transportation methods, and storage conditions can be tracked, thereby ensuring food security.

Stringent safety protocols are enforced within the facility, with zones designated and color-coded floors implemented to facilitate proper management of supplies and food production processes.

Regarding sustainability, Sagar emphasized, “When we initially planned the construction of our facility in India, we prioritized environmentally conscious building practices and integrated various sustainable initiatives into the design. These initiatives encompass energy efficiency, water conservation, and indoor air quality improvements, all aimed at reducing our carbon footprint.

Currently, our facility utilizes rainwater harvesting systems and advanced water recycling technology to decrease our reliance on groundwater by up to 50%. Furthermore, we’ve implemented ammonia, a natural refrigerant, in our cooling systems, which is more eco-friendly than traditional refrigerants.

Our future plans involve installing solar panels on the roof to generate approximately 20% of our energy needs. Additionally, we’re exploring strategies to minimize waste handling and costs, including the adoption of a wet waste dehydration machine.”

In preparation for the facility’s full operation, the company has hired 230 employees to date, with a significant portion recruited from nearby communities. Over half of these employees are women. To support working parents, particularly mothers, the SFSI team has established a daycare facility onsite. This facility not only aims to attract and retain talent but also includes dedicated spaces for mothers to nurse and bond with their infants.

“We prioritize the well-being of our employees and recognize the importance of achieving a healthy work-life balance. Providing access to daycare facilities demonstrates our commitment to supporting our employees’ needs, enhancing their productivity, and fostering greater engagement in their work,” Sagar stated.

Source: Hotelier India